VULKAN PRODUCTS

MOUNTS

The main goal of the marine engine mounts is to isolate the vibration generated by the engine and to absorb shocks / vibration when the vessel is cruising. The elastic properties of the marine engine mounts are essential to the prevention of engine damage and to improve the comfort of the boat's passengers.

products

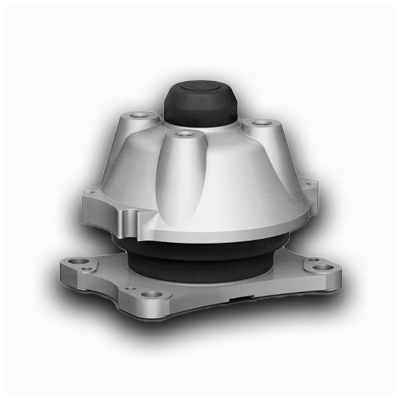

T Series

The highly elastic supports of the T series have been specially developed to meet the highest demands in terms of insulation and comfort; at the same time they offer a high degree of security with their diverse designs. The load is carried by rubber elements by means of shear and compression deformation.

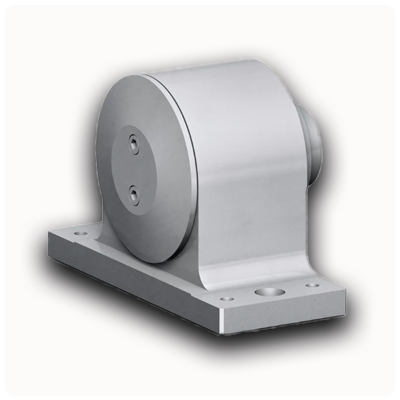

AVR Series

AVR mounts are semi-resilient and are primarily suitable for freestanding gearboxes and close-coupled engine/gearbox applications where the mounts must carry torque at full propeller thrust. The rubber element is able to absorb axial and, in particular, radial vibrations as well as gimbal loads.

CV Series

Bearings of the CV series are used for light/medium-heavy machines and systems, electric motors, combustion engines, control cabinets and as highly insulating gear bearings. The latter are connected to the gearbox and foundation by mounting plates.

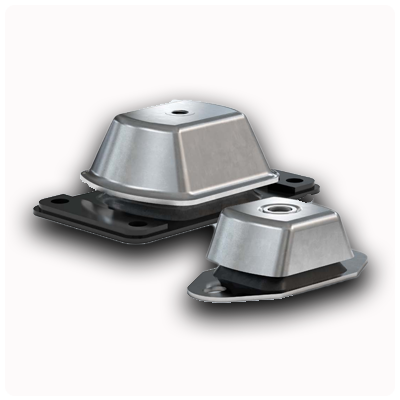

MG Series

The flexible mounts of the MG series have been developed for commercial, industrial and pleasure boating applications where low weight is crucial. For this reason, the standard versions are made of light metal. The damping element of the elastic mounts of the MG series consists of natural rubber (NR).

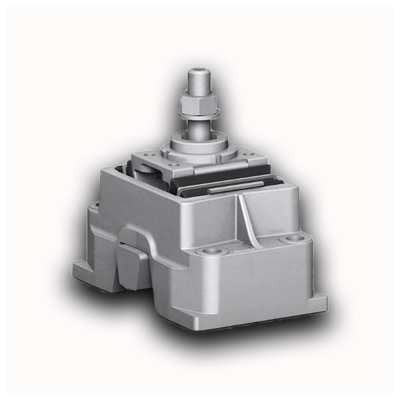

VDM Series

The VDM series delivers optimal performance in areas where insulation and stability are urgently required. The optimized stiffness ratio in the three directions guarantees good vibration isolation and at the same time the VDM series is able to absorb longitudinal loads. In the vertical and lateral directions, isolation is achieved through low rigidity.

VDM-M Series

The VDM-M series offers optimal performance in applications where cushioning and stability are crucial. The optimized rigidity in three directions ensures good vibration isolation. At the same time, the VDM-M series is able to absorb longitudinal loads. Insulation in vertical and lateral direction is achieved through low rigidity.

VD Series

The rubber elements of the VD series carry the load in combined shear and compression deformation, which achieves optimal vibration isolation performance of the mounted machine. Stability is ensured by the ratio of stiffness in the three directions of loading. The metal parts are treated with corrosion protection for outdoor use. The upper metal cover protects the rubber element from ozone, UV radiation, fuel or oil.

V Series

The highly flexible V Series was primarily developed for the storage of assembled engine-gearbox-drive systems. Due to tri-axial rigidity, the V series is ideal for thrust transmission with small displacements via the high longitudinal rigidity, while the remaining low rigidity of the other 2 axes guarantees excellent vibration isolation of the engine and transmission.

HD Series

The HD series vibration isolators are designed for shock isolating applications and are particularly suitable for marine propulsion, diesel generators and heavy machinery where a high degree of isolation of low frequency vibrations is required. The HD series offers dynamic deflection of up to 80 mm. Due to this property, the input loads caused by shock to the drive system are largely reduced.