Stay cool, Sail cool

Box Coolers

WEKA Marine specializes in providing durable heat exchangers, specifically designed for maritime applications. Their box coolers, a top choice for vessels, feature a space-saving U-tube bundle within the sea chest, offering reliable cooling by circulating seawater, either through forced movement or natural convection. The box coolers eliminate the need for an external water circuit, minimizing components like pumps and valves, and are made from anti-corrosive materials for long-lasting performance. Additionally, they offer anti-fouling solutions to counter biological growth. Overall, WEKA Marine ensures efficient, low-maintenance cooling systems tailored to marine environments, backed by decades of expertise. Browse below all WEKA Marine Box Coolers we can offer you.

We offer Next Day Shipping for your order to your located vessel.

PRODUCTS

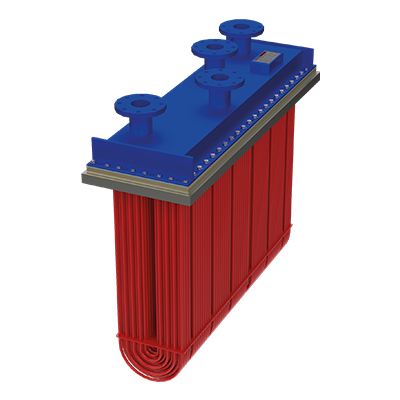

90/10 Copper - Nickel

WEKA’s signature box cooler is built with uncoated 90/10 copper-nickel tubing, chosen for its natural corrosion resistance and anti-fouling properties, eliminating the need for protective coatings or an ICAF system. To safeguard against stray current corrosion, WEKA applies its proprietary WEKA Guard™ and WEKA Protector™ systems. This robust design is successfully implemented in numerous vessels across both freshwater and saltwater environments globally.

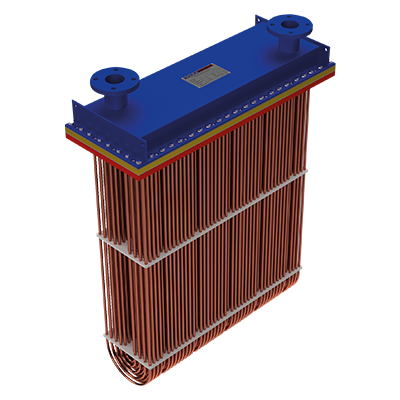

70/30 Copper - Nickel

Another effective cooling solution from WEKA is the uncoated 70/30 copper-nickel box cooler. With 30% nickel content, this alloy is stronger and can handle higher seawater velocities than the 90/10 alloy. Like its counterpart, it requires no protective coating or ICAF system due to its natural corrosion resistance and anti-fouling properties. To prevent stray current corrosion, WEKA employs its WEKA Guard™ and WEKA Protector™ Type T systems. This specialized design has been successfully implemented in various cooling projects worldwide.

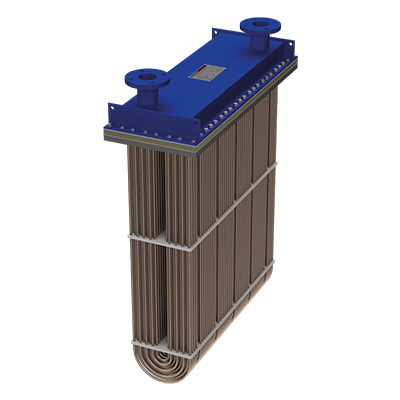

Coated Aluminum - Brass

Aluminum brass box coolers, widely used in the marine industry, are valued for their strength but require a protective phenol heat-cured coating and protection system due to their limited natural corrosion resistance and lack of anti-fouling properties. This coating shields the cooler from galvanic corrosion while maintaining high heat conductivity. Additionally, an anti-fouling system is necessary to prevent marine growth on the coated aluminum brass box coolers.