Stay cool, Sail cool

Box Coolers

These parts are manufactured by VULKAN COUPLINGS, Germany pioneers in marine drive technology.

Furtermore, VULKAN components are used in powerplant facilities or in industrial applications as well.

VULKAN production program includes following types, most available from the manufacturing site in Germany but some common ones are also available from our warehouse in Moschato:

70/30 Copper - Nickel

To protect the uncoated box coolers against potential stray current corrosion, a WEKA Guard™ and WEKA Protector™ Type T system are applied. This exclusive design is successfully utilized in specific cooling projects worldwide.

WEKA Protector™ and WEKA Guard™

Exclusive to WEKA box coolers are the WEKA Protector™ and WEKA Guard™. This equipment helps to minimize potential damage to the units and hull from stray electrical currents and galvanic corrosion. The WEKA Protector™ also allows the copper-nickel to maintain its anti-fouling capabilities, protecting the tubes from marine growth.

Technology

The versatility of the WEKA box cooler is equally matched by its cooling prowess. Its straightforward design can be adapted into various configurations and shapes to precisely fit available space and cooling demands.

A typical box cooler features a U-shaped tube bundle, firmly secured with a tube sheet and a waterbox to guide the flow of water. This bundle is fastened with a gasket to a mounting frame, anchoring the cooler to the vessel’s hull. This construction technique enables the removal of the waterbox while keeping the bundle fixed to the hull, preventing seawater from entering the vessel when the cooler is in use.

To cater to a broad spectrum of cooling requirements and diverse structural limitations, WEKA box coolers are available in multiple configurations, encompassing both round and rectangular designs.

Application

Marine Applications

Design Specifications

Design Pressure: 3.33 bar g

Test Pressure: 5.00 bar g

Design Temperature: 94.9 °C

Key Benefits

Less susceptible to corrosion and fouling

Can operate in icy conditions, silt or polluted waters

Low maintenance

Space-saving in the machine room

Low operational costs

Selection of Materials

Bonnet: Carbon Steel – Color coated

Tubesheet: Naval Brass

Support plate: Teflon

Tubes: Cu/Ni 70/30

Coating: N.a.

Bolts: Carbon Steel Galvanised

Gaskets: Rubber compound

Isolation Bushings: Yes

Additional equipment required: WEKA Guard & Protector

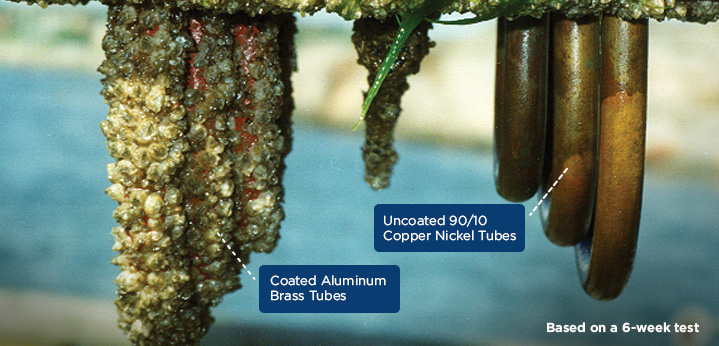

Natural Anti-Fouling/Amazing results after a 6 week feasibility study

This image compares traditional aluminum brass tubes with hard-baked coating (left) and uncoated 90/10 copper-nickel tubes (right) after a six-week feasibility test. The 90/10 Cu-Ni tubes show superior natural anti-fouling properties, effectively resisting algae, mussels, and other marine growth. This biofouling resistance comes from the copper in the protective oxide film, not from copper ion leaching, making copper-nickel alloys an excellent choice for marine environments.