Stay cool, Sail cool

Laser Plate Heat Exchangers

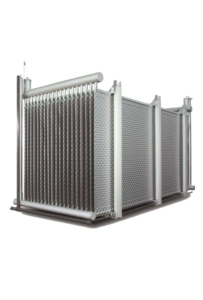

The Omega Laser Plate is engineered to regulate the temperature of fluids such as oil, water, and asphalt in a vessel’s cargo holds and to preheat these fluids before reaching port for efficient pumping. The Omega Laser Plate is made from two stainless steel sheets that are laser welded with a custom circular weld pattern. The outer edge of the plate is fully laser welded to create a secure pressure boundary. This autogenous welding process, performed by Omega’s advanced laser machines, fuses the materials without the use of filler materials.

The Laser Plate is safely inflated using hydraulic pressure from a hydrostatic pump, creating a cavity for heat transfer mediums like liquids, steam, or refrigerants. Alternative inflation methods can be employed based on specific applications.

We offer Next Day Shipping for your order to your located vessel.

PRODUCTS

Laser Plate Heat Exchanger

The Omega Laser Plate is specifically engineered to regulate and maintain the temperature of fluids like oil, water, and asphalt within a vessel's cargo holds. It also facilitates the preheating of these fluids before arriving at port, ensuring easier pumping. Constructed from two stainless steel sheets, the Omega Laser Plate is precision laser welded using a custom circular weld pattern. The plate's outer perimeter is fully laser welded to create a secure pressure boundary. This autogenous welding process, performed by advanced Omega laser machines, seamlessly fuses the materials without the need for filler materials.